For silicon wafer processing a

wafer needs to meet certain quality specifications, like chemical, mechanical,

surface specifications, and electrical specifications. It is important

that Epi wafer undergo these quality criteria so a wafer is

marked as defect-free and of excellent quality. For different electronic

applications, there is the use of high-quality wafers in semiconductor

manufacturing. To guarantee that the devices produced are efficient it goes

through a series of thorough processing, including epitaxial growth. This

article depicts epitaxial growth and its significance in manufacturing

semiconductors.

Epitaxial Growth or Epitaxy

Epitaxy plays an important role

in silicon wafer processing for semiconductor applications. Epitaxial growth or

epitaxy is a process in which over a single crystal substrate a fine layer of

single-crystal material is transferred along with the help of chemical vapor

deposition. Epitaxy is performed to boost and develop the performance of

bipolar devices. It helps in giving good control to the doping concentration of

the devices, therefore making the layers oxygen and carbon-free. An example is

the deposition of silicon over a silicon substrate. Epi wafer suppliers are

present everywhere to supply good quality wafers.

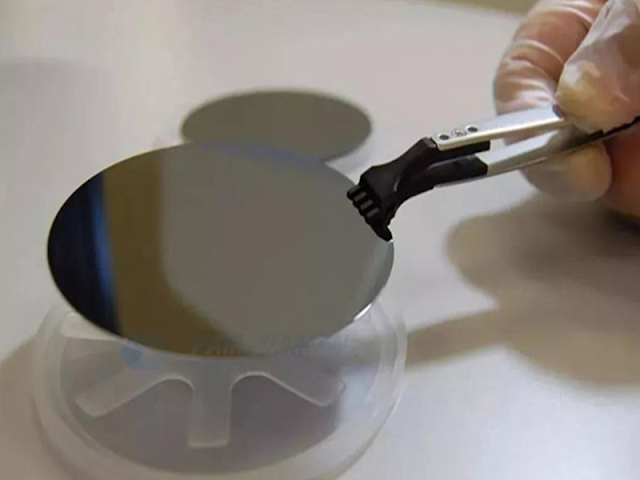

Silicon Wafer Processing

In producing high-quality wafers

meticulous and thorough silicon wafer processing plays a huge role. We provide

premium quality wafers at an affordable price at wafer world.

Finishing of the Process

With the use of an epitaxial

reactor, the chemical vapor deposition of epitaxial growth is attained. It

consists of a quartz reaction where a susceptor is placed. To the wafers, the

susceptor provides mechanical support and with thermal distribution, it creates

an environment. At high temperatures, an epitaxial deposition is performed

which allows gasses to flow into the chamber. In Silicon epitaxy, it is

observed that over thickly-doped silicon substrate there is the involvement of

growing a thinly doped epi layer. Across the collector-substrate junction, this

is done to achieve a higher disintegration voltage along with keeping low

collector resistance. A higher operating speed is permitted by a lower

collector resistance by using the same level of current. From Epi wafer

manufacturer you can easily manufacture wafers according to your

requirements.